UHP Waterjet Technology

UHP waterjet technology can pressurize ordinary water into water with the pressure of 100 Mpa to 400 Mpa. Then the water is jetted out at a high speed about 800 to 1000 m/s from the nozzle with the diameter of about 0.3 mm. This high pressure waterjet cutting machine contains high energy and can be used to cut soft materials. If sufficient abrasive is added to the machine, it can cut almost all soft and hard materials. By adjusting jet pressure and flow, UHP waterjet cutter can be used to clean various objects, such as degumming and removal of lacquer and rust. UHP waterjet technology can also be used for high pressure sterilization, food fresh keeping, and so on.

- Features

- High pressure waterjet cutting machine is suitable to cut a variety of materials, such as steel, copper, aluminum, ceramics, metal alloy, plastic, man-made fibers, fabric, paper and composite materials.

- This kind of waterjet cutter is an ideal tool for making structural components or welding joint units that are widely used in machinery manufacturing.

- High pressure waterjet cutting machine has been widely used in the aerospace, military industry, rail transit, shipbuilding, mechanical engineering, light industry, chemical industry, energy, construction, etc.

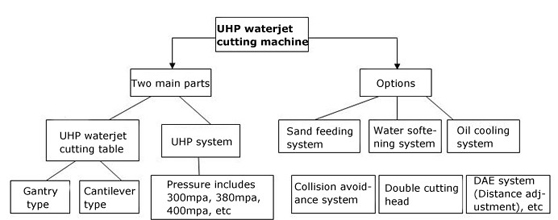

- UHP waterjet cutter consists of two parts: cutting table and high pressure system. Cutting table is used to support, position and fix work pieces. It is also the main part to move the water jet. Lantoky high pressure waterjet cutting machine is controlled by numerical control system. After being programmed, it can make any curve cutting for work pieces.

- High pressure system is the key part of the whole waterjet cutting system. After being filtered, water is pressurized up to 300 to 400 Mpa by a powerful water pressure pump, which continuously supplies high pressure water to the waterjet cutter. The efficiency, quality and accuracy of cutting and running cost are directly affect by water pressure, working stability, continuous working hours and the elements’ quality.

Established in 1996, Lantoky possesses over 15 years’ experience in developing and manufacturing high pressure waterjet cutting machines. In addition to making waterjet cutter, we also provide UHP waterjet cleaning system. Featuring great reliability, high cutting accuracy and competitive price, our products are extensively applied in the metal and glass cutting, and ceramics processing industries. Our products are CE certified and are well received in the U.S, Canada, Russia, Italy, Australia, Southeast Asia and Middle East.

English

English Español

Español Português

Português Français

Français Русский

Русский العربية

العربية Việt

Việt