- Plane Waterjet Cutting Machine

- Gantry CNC Waterjet Cutting Machine

- Cantilever CNC Waterjet Cutting Machine

- UHP System

- Robot Water Cutting System

- UHP Waterjet Cleaning System

- UHP Waterjet Cleaning System (Intensifier)

- UHP Waterjet Cleaning System (Three Plunger Pump)

- Waterjet Options

- Auto abrasive Delivery System

- Collision Avoidance System

- Double Cutting Head

- Water Softening System

- Oil Cooling System

- Case

- Automobile Manufacturing

- Stone and Ceramic Processing

- Glass Processing

- Metal Processing

- Concrete Cutting

- Composites Processing

- Other Areas

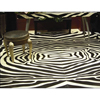

Stone and Ceramic Processing

Lantoky waterjet cutting table is an ideal choice for creating corporate logos in decorative designs on walls or inlaid into floors, countertop parts, faucet and sinkholes as well as a smoother. We can provide waterjet cutting solutions widely applied in the manufacturing of large ceramic murals, pottery screens, parquet floors, bathroom countertops, stone-made furniture, etc. Our waterjet cutting tables are perfect for job shop or processing workshop owners who can use the machine to do stone cutting, marble cutting, granite cutting and tile cutting.

- Advantages of Lantoky Waterjet Cutting Solutions

- Waterjet cutting is increasingly used in many industries, especially stone and ceramic processing industry. Our waterjet cutting tables have the following advantages.

- Kerfs are smooth. Cutting performance is excellent. Besides, waterjet cutting eliminates most secondary finishing with no rough edges.

- Our waterjet cutting solutions can achieve cutting the most intricate stone, tile and marble with high cutting efficiency and accuracy. The accuracy can be 0.1 mm. Hence, it is suitable to make mural or picture puzzle.

- Lantoky waterjet cutting tables produce little noise and dust during waterjet cutting process, which can improve the work environment. There is also little or no waste of raw material, no toxic fumes or dust in contrast to saws and blades.

- Our waterjet cutting solutions eliminate the risk of discoloring or deformation.

- Waterjet cutting table for stone and tile is equipped with flexible saw and waterjet combined system.

- Using a waterjet cutter to make parquet floor can greatly improve efficiency and reduce labor cost. In addition, we can save 40 % of materials costs because plenty of wastes can be recycled. The price of finished parquet floor is nearly 20 times the price of waste materials. Customers can get back their original investment in three months.

- FAQ about Lantoky Waterjet Cutting Solutions

- 1. How fast can the material be cut?

- The cutting speed of our waterjet cutting tables is determined by pump pressure, efficiency of high pressure generation and cutting head configuration, material thickness and properties, desired cutting edge quality, orifice diameter, abrasive quantity and abrasive quality.

- 2. What is the maximum material thickness that can be cut according to Lantoky waterjet cutting solutions?

- We recommend the maximum material thickness of about 25 cm.

Lantoky is a professional waterjet cutter manufacturer in China. We can offer waterjet cutting solutions for customers. Our products mainly cover plane waterjet cutting table, ultra high pressure waterjet pump, UHP waterjet cleaning system, and so on. They are extensively applied in automobile manufacturing, glass processing, metal processing, concrete cutting, composites processing, etc.

English

English Español

Español Português

Português Français

Français Русский

Русский العربية

العربية Việt

Việt